Well, after the Christmas break, we got back to it, finishing up the attic insulation.

Initially, we had thought we would subcontract this job, never having attempted it before ourselves. So, we got a quote on the job from a recommended subcontractor. He quoted us a rate of $1.50/sf for R-30 insulation blown in to the attic. For approximately 2600 sf (just the main part of the house — not the WWII museum and research center), this equates to a cost of $3900. We actually wanted more insulation — up to R44, so we decided to see how difficult it might be to do it ourselves.

It turns out not to be very difficult or time-consuming. Oz went to the local Home Depot, where he found out they allow use of their machine for free if you purchase the insulation material from them. They calculated how much material would be needed for the 2600 sf for R44 insulation. Lo and behold… it came out to be only about $1700 total. Not knowing for sure how much extra the contractor would have charged for R44 vs R30 insulation, we don’t know exactly how much we saved, but we figure it is about $2500 (certainly no less than $2200).

The job does take two people — one to man the blower end in the attic — one to load the machine continuously. It is messy work, requiring goggles, facemasks and gloves to be worn. However… all that being said, we were completely finished in only two days. We figured it was a good use of our time and well-earned sweat equity on the house. We have found a definite difference in the constant temperature inside the house since it was done, even though we haven’t finished all the mudding and taping of the sheetrock to seal the cracks.

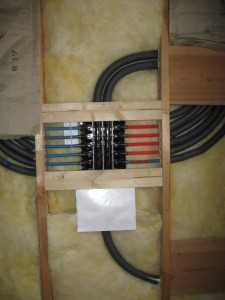

Here are photos of the machine and the result in the attic: