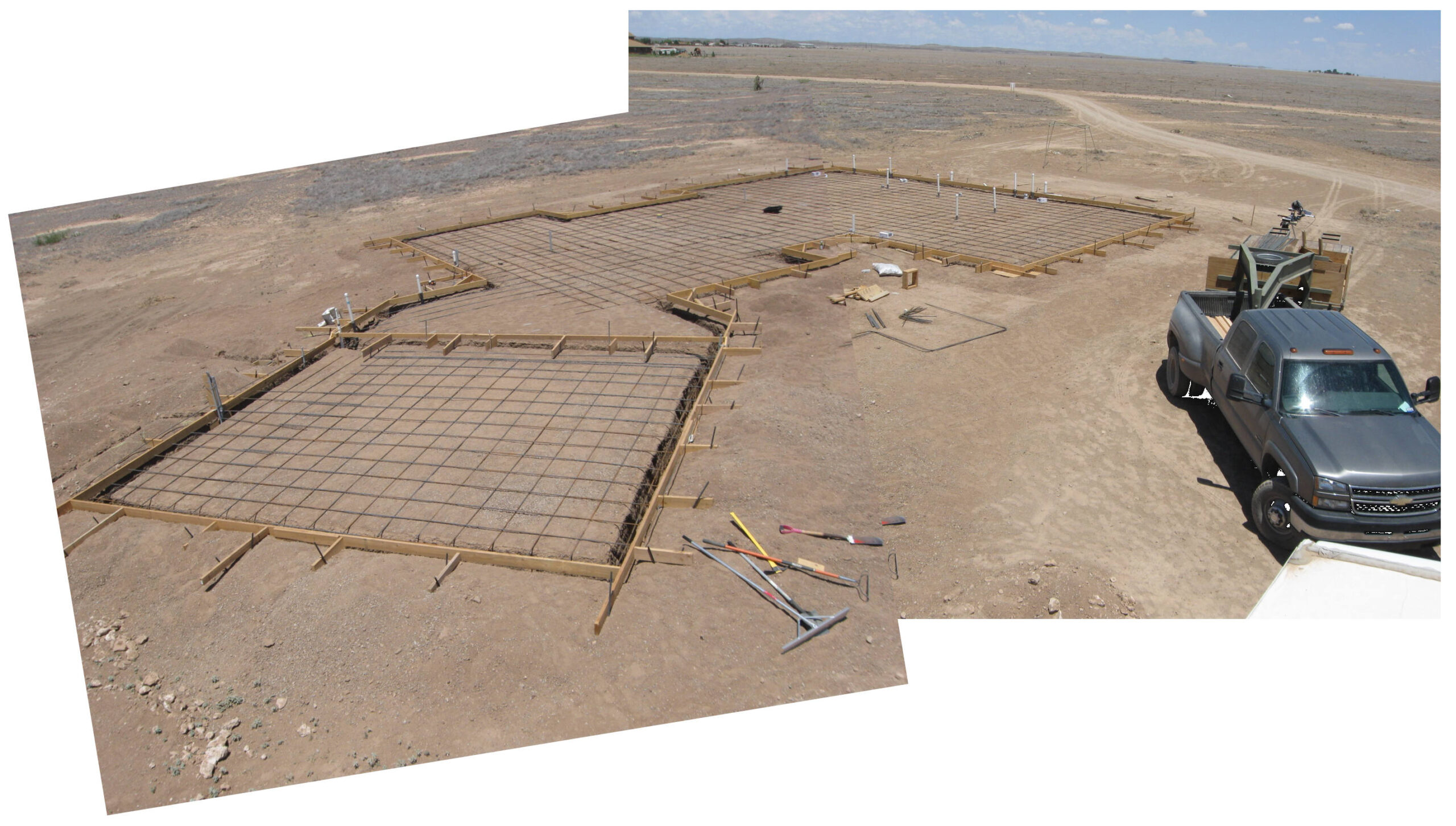

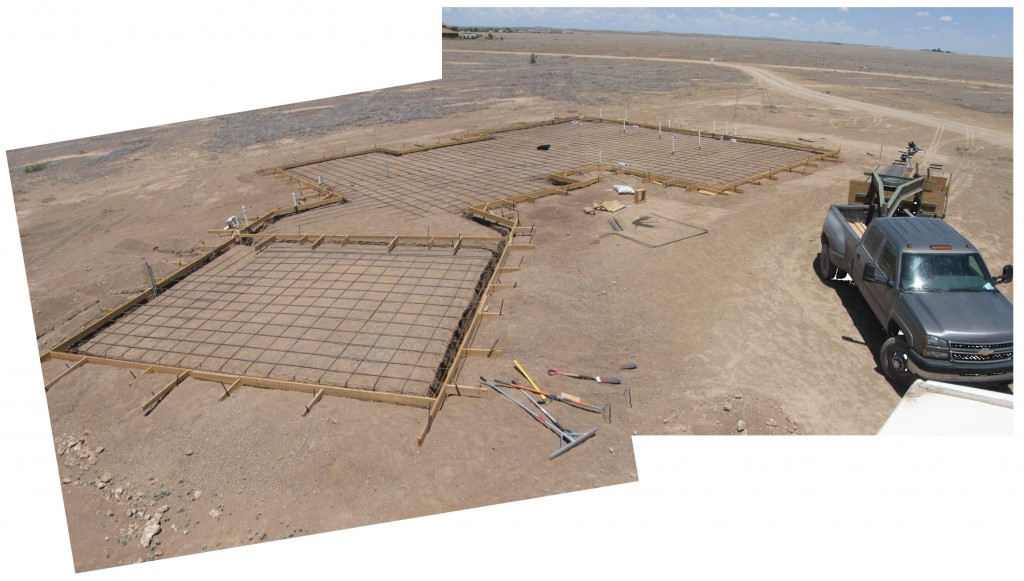

After several weeks’ worth of preparation (I had no idea there was so much involved before we did this ourselves), the foundation pour happened! Two nights before the pour (Sunday evening), we got a wonderful heavy rainfall. We were concerned at first that it might do damage to the trenches, but all was well. Our concerns over the muddy road were also unfounded.

Then Monday evening, we got another heavy rainfall (have I mentioned that we have not had any rain since May prior to this?). Again, we were concerned over the road conditions and the possible damage to the trenches. At 5:05 a.m., the subcontractor who would be doing the actual pour pulled into our drive. He said all was well with the road and the trenches, so the pour was on! Soon after, his son, cousin and two other workers arrived. At just after 6:00 a.m., the first concrete truck arrived.

They began with the footers, starting with the wall between the house and garage. Since there is a step-down between house and garage, that portion needed to dry a bit before the lower garage level would be poured. Pouring it first allowed the braces to be removed before the garage pour.

The subcontractors worked really well together and did a great job. If you are interested in getting concrete work done in SE New Mexico, we would highly recommend them (Samuel Castro 575-420-6615). We were also very happy with the service offered by Roswell Ready Mix (575-622-1186) . They have a large fleet of trucks and were able to handle the timing required for a good steady supply of concrete for the subcontractor.

We chose to have 3000 psi concrete plus the added fiberglass to add more strength to the foundation. Since we are considering doing a concrete floor stain, we want to try to avoid even small surface cracking as much as possible.